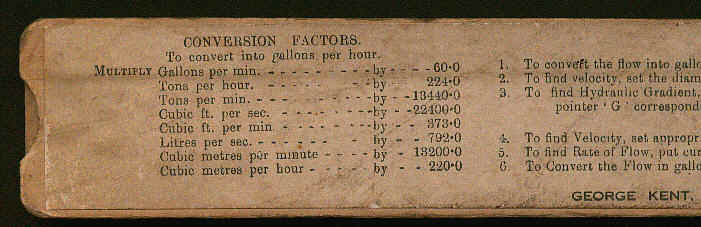

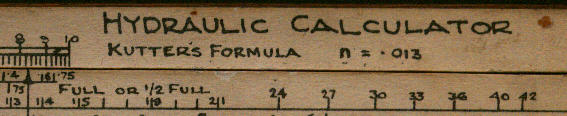

1. This slide rule was made by George Kent, a company founded in

1883 which made water meters. Its meters are still sold under the name of ABB-Kent.

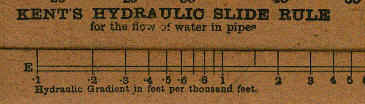

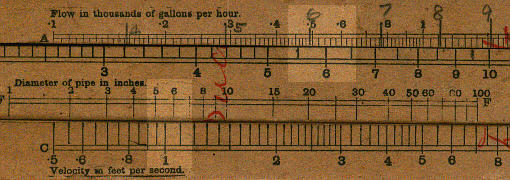

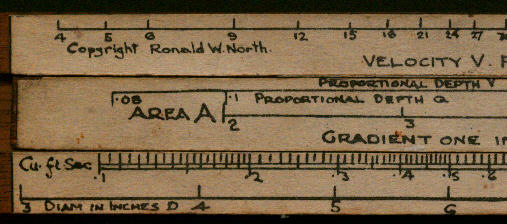

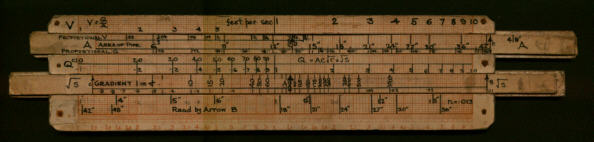

2. The rule is designed to calculate flow in pipes.

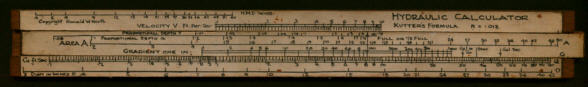

3. The rule does not carry an explanation of which formula is used for the calculation.

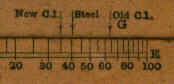

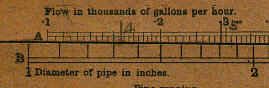

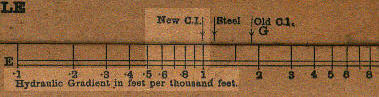

4. It's use very simple. By placing the gauge mark for the appropriate material against

the hydraulic gradient, the flow or velocity can be read against the pipe diameter on the

appropriate scale.

5. The rule is made of cardboard and does not need a cursor.

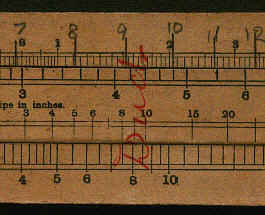

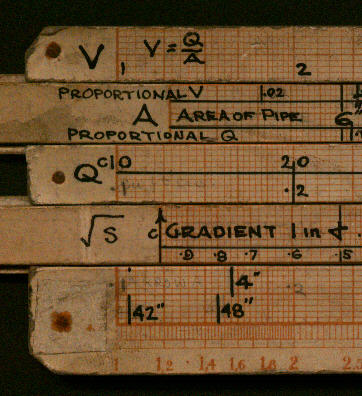

6. I have two identical rules, obtained at the same time. This one has the word "Dud" written on it and some numbers hand written against one

of the scales. The other rule does not. I give below my explanation as to why someone

wrote those words on the rule.